SPECIAL PRINT

SPECIAL PRINT, FIREPROOF PRINTWORK, SAFETY SIGNS

Pelikan-Group company is glad to offer production of posters and signs of electrical safety, fireproof printwork and also floor and wall marking of any parameters for production rooms to the clients.

| Prices for special print (download) |

According to clause 3.8 of Fire Safety Regulations, in Ukraine, the territory of the enterprise, as well as buildings, constructions and rooms must be provided with the corresponding safety signs according to standard GOST 12.4.026-76 * “color coding and safety signs”.

It is also necessary to put fire safety signs in places and sites, which temporarily have explosive and fire hazard.

The fire safety signs are designed to attract the attention of workers to the immediate danger, to warn about possible dangers, to regulate and permit certain actions to ensure fire safety and to provide the necessary information.

The fire safety signs, which are installed at the entrance to the room (at the gates, entrance doors), mean that the action of these signs covers the entire room. If it is necessary to limit the area of action of the sign, the appropriate explanation should be given in the explanatory inscription.

There are several groups of safety signs, including fire safety signs: prohibiting signs are used to prohibit certain actions; warning signs - to inform workers about possible danger; compulsory signs - to allow worker to do actions only under the specific fire safety requirements and to indicate evacuation routes; information signs - used to indicate location of fire hydrants, hydrants, fire extinguishers, fire alarm, areas for smoking, emergency exits, etc.

PROHIBITING SAFETY SIGNS

The signs are used to prohibit certain actions.

According to the technical requirements of standard DSTU ISO 6309:2007, the prohibiting signs shall be as follows: a red circle with a white field inside, with a white border around the outline of the sign and a black symbolic image on the inner white field crossed out by a slanting red stripe (inclination angle - 45°, from left top to right bottom). The width of red color ring should be 0,09-0,1 of outer diameter and the width of the slanting red stripe - 0,08 of outer diameter, width of the white border around the sign outline - 0.02 of the outer diameter.

It is allowed to use prohibiting signs with an explanatory inscription made in black print. At this, slanting red stripe is not made on the sign.

The method of applying of safety signs on production machinery and their dyeing with paintwork materials in color coding is specified in the design documentation. The method of application must ensure the preservation of signs and color coding throughout the service life of the equipment or till its overhaul.

The paintwork materials of color for coding, which are used for painting of prohibiting safety signs, production equipment and other objects, shall provide stability of color of covering in climatic and production conditions, for which safety signs, production equipment and other objects are designed.

Prohibiting signs, which are used in the dark or in low visibility conditions, must be illuminated. All devices, which provide visibility of signs, tablets and blocks in the dark, should not change their color and should not affect their visibility in the daytime.

Flat signs, tablets and blocks bearing prohibiting signs must be made of sheet metal with a thickness of 0.5 to 1.5 mm, and also of plastic or wood, provided that the necessary strength, stiffness and stability under different atmospheric conditions is ensured.

The limit deviations of the overall dimensions of signs and tablets is ± 2 per cent.

COMPULSORY SAFETY SIGNS

The compulsory safety signs are designed to indicate specific requirements for occupational safety (mandatory use of certain means of protection by the workers).

According to technical requirements of standard DSTU 6309: 2007, the signs shall be as follows: the circle of blue color with the white border on the outline (width of 0,02 of sign diameter), in which there is a symbolical image in white color.

To add the explanatory inscription, it is necessary to draw a white field with a diameter of 0,7 of sign diameter inside a blue circle.

The method of applying of safety signs on production machinery and their dyeing with paintwork materials in color coding is specified in the design documentation. The method of application must ensure the preservation of signs and color coding throughout the service life of the equipment or till its overhaul.

The paintwork materials of color for coding, which are used for painting of safety signs, production equipment and other objects, shall provide stability of color of a covering in climatic and production conditions, for which safety signs, production equipment and other objects are designed.

The signs, which are used in the dark or in low visibility conditions, must be illuminated. All devices, which provide visibility of signs, tablets and blocks in the dark, should not change their color and should not affect their visibility in the daytime.

Flat signs, tablets and blocks bearing signs must be made of sheet metal with a thickness of 0.5 to 1.5 mm, and also of plastic or wood, provided that the necessary strength, stiffness and stability under different atmospheric conditions is ensured.

WARNING SAFETY SIGNS

This group of signs is designed to warn workers of possible dangers.

According to standard DSTU 6309: 2007 warning signs shall be as follows: an equilateral yellow triangle with rounded corners, facing upwards, which has a black border with a width of 0.05 side and a symbolic black image.

The method of applying of safety signs on production machinery and their dyeing with paintwork materials in color coding is specified in the design documentation. The method of application must ensure the preservation of signs and color coding throughout the service life of the equipment or till its overhaul.

The paintwork materials of color for coding, which are used for painting of safety signs, production equipment and other objects, shall provide stability of color of a covering in climatic and production conditions, for which safety signs, production equipment and other objects are designed.

The signs, which are used in the dark or in low visibility conditions, must be illuminated. All devices, which provide visibility of signs, tablets and blocks in the dark, should not change their color and should not affect their visibility in the daytime.

Flat signs, tablets and blocks bearing signs must be made of sheet metal with a thickness of 0.5 to 1.5 mm, and also of plastic or wood, provided that the necessary strength, stiffness and stability under different atmospheric conditions is ensured.

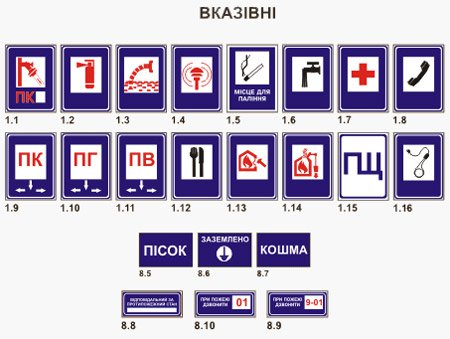

INFORMATION SAFETY SIGNS

Information safety signs are used to indicate the location of various objects and devices.

According to standard DSTU 6309: 2007 signs should be as follows: blue rectangle, which has a white border (the width of 0.02 of the smaller rectangle side) along the outline and white square (the width of 0.7 of the smaller rectangle side) inside. The symbolic image or explanatory inscription in black color must be inside the white square.

On the information signs it is allowed to indicate a pointer and distance to an object in white color directly in the bottom part of the sign (under the white square).

It is allowed to combine the information signs, which are provided by this standard, with the explanatory inscription in the uniform block of the rectangular form. The information sign must be on the left side of the block. The height of the block should be 15% higher than the height of the sign, the length of the block - 2 or 3 times its height. The block must have border with the width of 0.05 length of the smaller side of the rectangle. Its color should match the color coding of sign.

The explanatory inscription should be black on a white background, with the exception of fire safety inscriptions, which should be red. The vertical arrangement of the block on the bigger side is allowed.

The method of applying of safety signs on production machinery and their dyeing with paintwork materials in color coding is specified in the design documentation. The method of application must ensure the preservation of signs and color coding throughout the service life of the equipment or till its overhaul.

The paintwork materials of color for coding, which are used for painting of safety signs, production equipment and other objects, shall provide stability of color of a covering in climatic and production conditions, for which safety signs, production equipment and other objects are designed.

The signs, which are used in the dark or in low visibility conditions, must be illuminated. All devices, which provide visibility of signs, tablets and blocks in the dark, should not change their color and should not affect their visibility in the daytime.

Flat signs, tablets and blocks bearing signs must be made of sheet metal with a thickness of 0.5 to 1.5 mm, and also of plastic or wood, provided that the necessary strength, stiffness and stability under different atmospheric conditions is ensured.

INFORMATION SIGNS

Inscriptions on signs:

1.1. - fire plug

1.5. - place for smoking

1.9. - fire plug

1.10 - fire hydrant

1.11 - fire water supply

8.5 - sand

8.6 - grounded

8.7. - fire blanket

8.8 - picture of the sign is unreadable

8.10 - In case of fire call 01

8.9 - In case of fire call 9-01

INFORMATION SIGNS

Inscriptions on signs:

8.1 - Exit here

8.2. - Enter here

8.3. - Work here

8.3 - Gas

8.4 - Gas

FIRE SAFETY SIGNS

Fire safety signs are used for indication of location of various objects and equipment for extinguishing and prevention of the fire, such as fire posts, fire plugs, hydrants, fire extinguishers, fire alarm posts, fire ladders, etc.

According to the technical requirements of standard GOST 12.4.026-76, fire safety signs should be as follows: a blue rectangle, which has a white border (the width 0.02 of the smaller rectangle side) along the outline and white square (the width 0.7 of the smaller rectangle side) inside. The symbolic image or explanatory inscription in red color must be inside the white square.

However, when the standard DSTU ISO 6309:2007 entered into force, the graphic image of a number of fire safety signs started look like this - a red square, inside of which there is a white symbolic image.

The types, sizes and colors of fire safety signs are regulated by the document

Standard GOST 12.4.026-76 (2.2 MB) “color coding and safety signs” and

Standard DSTU ISO 6309: 2007 (1.7 MB) “Fire safety. Safety signs. Form and color”. Besides that, at choosing and installation of fire safety signs, it is necessary to comply with the current standards, construction norms and rules of fire safety.

The manufacturing of photoluminescent (glow in the dark) fire safety signs is also possible. The main advantage of such signs is increased visibility in conditions of power outages or smoke in the room in case of a fire. The use of photoluminescent signs makes it possible to quickly evacuate personnel without panic and to detect and apply all available means of fire extinguishing in time, even in conditions of absolute darkness or poor visibility.

The paintwork materials of color for coding, which are used for painting of prohibiting safety signs, production equipment and other objects, shall provide stability of color of a covering in climatic and production conditions, for which safety signs, production equipment and other objects are designed.

The signs, which are used in the dark or in low visibility conditions, must be illuminated. All devices, which provide visibility of signs, tablets and blocks in the dark, should not change their color and should not affect their visibility in the daytime.

Therefore, a number of requirements must be met, when choosing their installation locations. Firstly, the sign must be clearly visible, the color of the surrounding background or foreign objects must not interfere with its perception. Secondly, the distance between the same signs indicating the location of the emergency exit or fire extinguishing technical equipment must not exceed 60 meters. Finally, the last requirement - the sign must be located in close proximity to the object, to which it refers.

The effectiveness of usage of fire safety signs directly depends on correctness of their placement, precise execution and illumination. The main instruments, which are used to extinguish a fire, must be located near signs of fire plug and fire extinguisher. Such signs as fire water supply, fire hydrant, fire plug and fire dry riser, which clearly indicate the location of these objects, will help fire team to complete their work in the shortest time possible and as effectively as possible.

The fire safety signs, which are installed at the entrance to the room (at the gates, entrance doors), mean that the action of these signs covers the entire room. If it is necessary to limit the area of action of the sign, the appropriate explanation in the explanatory inscription should be given.

Flat signs, tablets and blocks bearing signs must be made of sheet metal with a thickness of 0.5 to 1.5 mm, and also of plastic or wood, provided that the necessary strength, stiffness and stability under different atmospheric conditions is ensured.

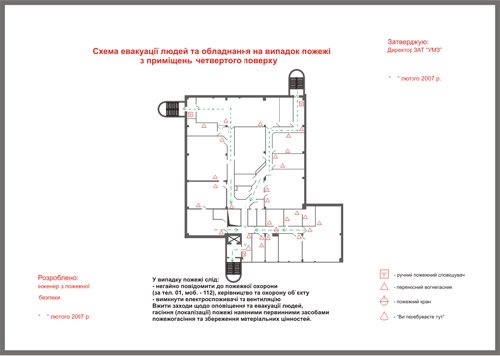

EVACUATION SAFETY SIGNS

Evacuation signs are intended to indicate the ways of evacuation in an emergency situation.

Evacuation signs according to the technical requirements of DSTU ISO 6309: 2007 should be as follows:

Green square or rectangle with a white border of width on the outline, inside of which there is white symbolic image.

Indicators for evacuation or emergency exits should be provided with their own autonomous power sources for lighting.

Paintwork materials used for the coloring of evacuation signs should ensure the color stability of the coating in climatic and production conditions for which the safety evacuation signs are designed.

Evacuation signs used in the dark or in conditions of poor visibility should be illuminated with autonomous power sources. All devices that provide visibility of signs, plates and blocks in the dark, should not change their color, and also worsen their visibility during daylight hours.

Flat signs, plates and blocks including evacuation safety signs should be made of sheet metal with thickness of 0.5 to 1.5 mm, as well as of plastics or wood, provided that they have the necessary strength, rigidity and stability under different atmospheric conditions.

POSTERS AND ELECTRICAL SAFETY SIGNS.

DESIGNATION AND REQUIREMENTS TO THE CONSTRUCTION

Depending on the conditions of use, posters and electrical safety signs can be as follows:

-

Prohibiting posters - to prohibit actions with switching devices, which, if they were turned on by mistake, can lead to voltage on the work site; for the prohibition of movement without means of protection in the ÎÐÓ 330 kV and higher with an electric field strength of more than 5 kV / m;

-

Warning posters – to warn of the danger of approaching to the conductive parts under current;

-

information posters – to allow the resolution of certain actions - only if specific labor safety requirements are met;

-

Pointing posters – to indicate the location of various objects and devices.

By the nature of the application, posters and electrical safety signs can be permanent and portable.

Posters and electrical safety signs should be made of electrical insulating materials (fiberglass, polystyrene, PVC, getinax, textolite, etc.).

For electrical installations with open live parts, portable and temporary hinged electrical safety signs made of conductive material are not allowed.

It is allowed to produce permanent, portable posters and safety signs from metal - only for installations that are distant from live parts.

Posters and signs of electrical safety on concrete and metal surfaces of ÂË supports, camera doors, etc. are recommended to be applied with stencils, as well as posters and electrical safety signs on self-adhesive film.

Painting materials of signal colors used for painting electrical safety signs, production equipment and other objects should ensure the color stability of the coating in climatic and industrial conditions for which electrical safety posters, production equipment and other objects are intended.

Posters and electrical safety signs, used in the dark or under conditions of poor visibility, should be illuminated. All devices that provide visibility of signs, plates and blocks in the dark, should not change their color, and also worsen their visibility during daylight hours.

Electrical:

6.1 Don’t go inside! It might kill you!

6.2 Stop! Current!

6.3 Warning! Danger for life!

6.4 Don’t climb up! It might kill you!

6.5 Dangerous electric field! The entry is prohibited without means of protection!

6.6 Don’t turn on! Men at work

6.7 Don’t turn on! Work on line!

6.8 Do not close! Men at work

6.9 Do not open! Men at work

6.10 Working under current! Do not turn on repeatedly

Consumer information board Fire safety propaganda and agitation

Èçãîòîâëåíèå ñòåíäîâ.

Ôîðìàò, ðàçìåð è äèçàéí ñòåíäà çàâèñèò îò æåëàíèÿ çàêàç÷èêà.

Making of stands

The format, size and design of the stand depends on the customer's desire.

PHOTOLUMINESCENT SAFETY SIGNS

In conditions of insufficient illumination or darkness, the color perception of unlighted objects deteriorates sharply or completely disappears. To improve the visual perception under these conditions, light-accumulating (photoluminescent) means of visual information are used.

Photoluminescent (light-accumulating) safety signs should be used where emergency shutdown of light sources is possible, and also they should be used as elements of photoluminescent evacuation systems to ensure independent entry of people from hazardous areas in case of emergency.

Photoluminescent objects in the dark independently emit a yellow-green glow, which causes the biggest activity of sensitive receptors in the human eye and allows visual perception of the necessary safety information.

The threshold of light sensitivity (the minimum intensity of light exposure, causing a sense of light) changes in the process of adapting the organs of vision to external light exposure. The highest sensitivity is achieved with adaptation in the dark for three to four hours, which helps to ensure the visibility of photoluminescent safety signs and signal markings for a long time.

The types, sizes and colors of fire safety signs are governed by the DSTU ISO 6309: 2007 (1.7MB) “Fire Safety. Safety Signs. Form and Color”. In addition, in the selection and installation of photoluminescent safety signs you should be guided by building regulations and fire safety rules.

|

Types of signs | ||

|---|---|---|

|

Regular |

In dark | |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

|

|

| |

TECHNICAL REQUIREMENTS FOR PHOTOLUMINESCENT SIGNS

The method of applying photoluminescent safety signs and its coloring with paint and varnish materials of signal colors is established in the design documentation. The paint and varnish materials should provide visibility of signs after switching off the lighting or in smoke conditions for a long (up to 7 hours) period.

Painting materials of signal colors used to paint safety signs and other objects should ensure the color stability of the coating in climatic and production conditions for which photoluminescent safety signs, production equipment and other objects are intended.

Flat signs, plates and blocks including evacuation safety signs should be made of sheet metal with thickness of 0.5 to 1.5 mm, as well as of plastics or wood, provided that they have the necessary strength, rigidity and stability under different atmospheric conditions.

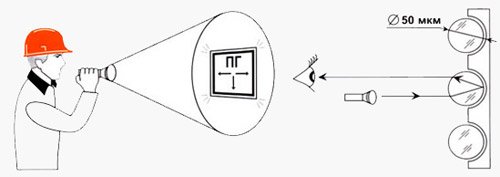

LIGHT-REFLECTING SAFETY SIGNS

Light-reflecting safety signs are designed for use in situations where information needs to be provided with insufficient visibility (illumination is less than 20 lux). The principle of light-reflecting signs is that to obtain the effect of light reflection it is necessary to apply a directional light source, for example, a flashlight or car headlights. This type of safety signs are made using special films and reflective paints that have in microballs in the mass and on the surface. When illuminated by a directional beam of light, the microballs reflect a part of the light flux towards the light source. Reflective films for the manufacture of signs are used for single and small print runs (1-100 pcs.), If the print run of safety signs of one type is more than 100 pcs., then you use reflective paints.

Any sign from the following can be made reflective:

Prohibition

Prescriptive

Warning

Information

Fire safety

Evacuation

For electrical installations